Summary

In electron beam lithography, any larger pattern than a writing field is subdivided into multiple writing fields. If writing field alignment isn’t perfect, stitching errors occur. Precise stage movement and precise beam positioning are essential to minimize the errors.

- select language:

- En

Perfect writing field alignment can avoid stitching errors. In the ideal case, the stage of the EBL system exactly equals the writing field size.

EBL system takes care of the writing field alignment. So,getting good writing field alignment is dependent on the EBL system.

How to minimize stitching errors? There are two tool factors to improve writing field alignment: (1)precise stage movement and (2)precise beam positioning

Precise stage move is essential to minimize stitching error. It can be achived by using a laser interferometer that can measure the stage position with 0.31nm resolution

Precise beam position can reduce stitching errors. A 20 bit DAC provides high beam positioning resolution.

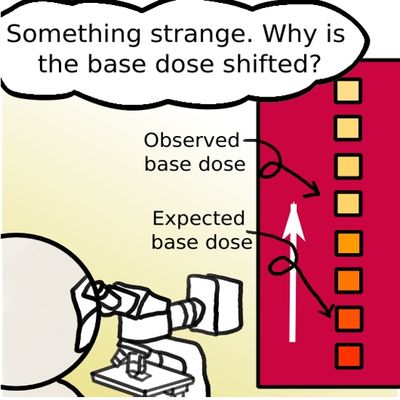

More beam deflection leads to more stitching errors. Therefore, using a smaller field reduces the errors but the writing time increases. Choose an optimized field size for your application considering write time and stitching error. It is wise to pay attention to the flatness of sample. Otherwise, deflection scale error caused by the change in sample height will occur.

There is always going to be stitching errors because the EBL tool is not perfect. CAD solution is recommended to reduce the errors. Create a writing strategy first and design your pattern. Don’t forget performing field correction with good step height of the brightness of the reference mark prior to exposure.

- Scroll to:

- Previous

- Ep2

Reference

- Cen, Shawn W, et al. High-energy Electron Beam Lithography for Nanoscale Fabrication. INTECH Open Access Publisher, 2010.

- Chen, ChiiDong. “Advanced Device Fabrication Techniques.” Institute of Physics, Academia Sinica. Lecture.

- “Elionix Electron Beam Lithography System ELS-G100.” Wisconsin Center for Microelectronics (WCAM), UW-Madison College of Engineering, wcam.engr.wisc.edu/Public/Tools/Lithography/Elionix%20ELS-G100%20Operating%20Procedure.pdf.

- “Introduction to ebeam Lithography.” Materials Research Science and Engineering Center – UW–Madison, mrsec.wiscweb.wisc.edu/wp-content/uploads/sites/282/2018/04/Yong-Sun.pdf.

- “Electron-Beam Lithography Training.” Welcome | Yale Institute for Nanoscience and Quantum Engineering, nano.yale.edu/book/export/html/213.

- “ELIONIX ELECTRON BEAM LITHOGRAPHY SYSTEM ELS-G100.” Wisconsin Center for Microelectronics (WCAM), wcam.engr.wisc.edu/Public/Tools/Lithography/Elionix%20ELS-G100%20Operating%20Procedure.pdf.

- “EOL JBX-9300FS Electron Beam Lithography System Training.” Nanolithography, www.nanolithography.gatech.edu/JEOL_JBX-9300FS_Training.pdf.

- “EBeam Basics 1.” Washington Nanofabrication Facility, Electron Beam Lithography, ebeam.mff.uw.edu/ebeamweb/doc/exp/exp/exposure_basics_1.html.

- “E-beam Lithography.” Vor Brodie and Julius Muray ”The Physics of Micro/Nano-Fabrication”, fy.chalmers.se/~yurgens/FKA196/lectures/E-beam%20lithography.pdf.

- Bogdanov, Alexei L., et al. “Electron-beam lithography for photonic waveguide fabrication: Measurement of the effect of field stitching errors on optical performance and evaluation of a new compensation method.” Journal of Vacuum Science & Technology B, Nanotechnology and Microelectronics: Materials, Processing, Measurement, and Phenomena, vol. 30, no. 3, 2012, p. 031606.

- “EBeam Basics 2.” Washington Nanofabrication Facility, Electron Beam Lithography, ebeam.mff.uw.edu/ebeamweb/doc/exp/exp/exposure_basics_2.html.

- “E-beam Lithography: Stitch Patch Offsets.” Nanostructure Physics, www.nanophys.kth.se/nanophys/facilities/nfl/manual/poslist/jochen-style/stich-pad-offset.html.

- “Introduction to EBPG Principle.” Welcome | Yale Institute for Nanoscience and Quantum Engineering, nano.yale.edu/book/export/html/253.

- “JEOL JBX-9300FS Electron Beam Lithography System Training.” Nanolithography, www.nanolithography.gatech.edu/JEOL_JBX-9300FS_Training_files/frame.htm.

- “Sample Height – Electron Beam Lithography: Guide.” Pythography: Practical Knowledge for Nanofabrication and Microfabrication, www.pythography.com/ebeam-lithography/sample-height.html.

Leave a Reply