Summary

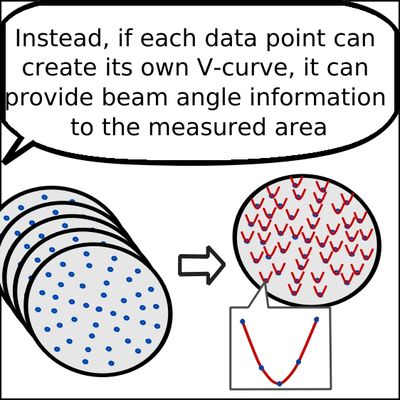

The main criteria for choosing the appropriate resist depend on the minimum

feature size, sensitivity, contrast and etching resistance. There is a large number of parameters affecting the EBL process in a complex, interacting fashion. Therefore, a better understanding on the complexity of these interactions can lead to a succcessful EBL

- select language:

- EN

- KR

Four main properties to characterize E-beam resists

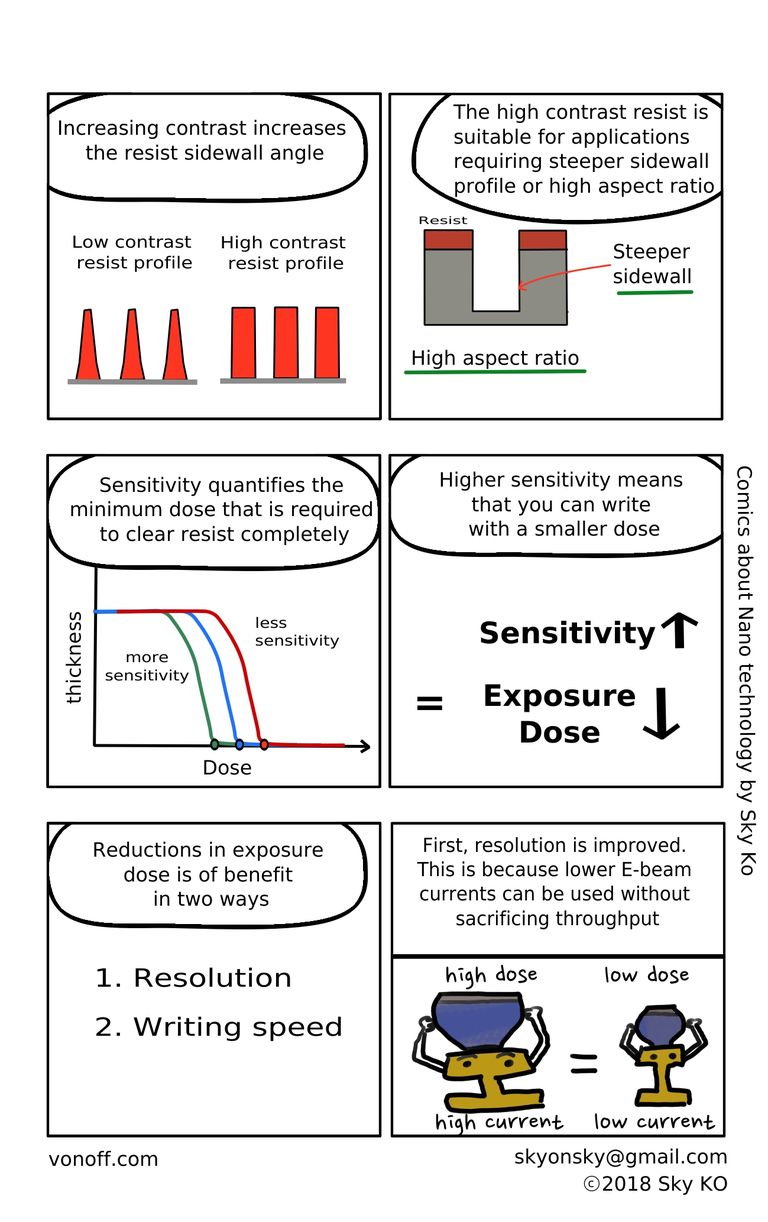

Contrast(γ) describes how abrupt is the dependence of thickness on dose

The higher sensitivity of E-beam resist indicates that the clearance dose is reduced. Therefore, using a more sensitive E-beam resist is a benefit in terms of improving resolution and writing speed

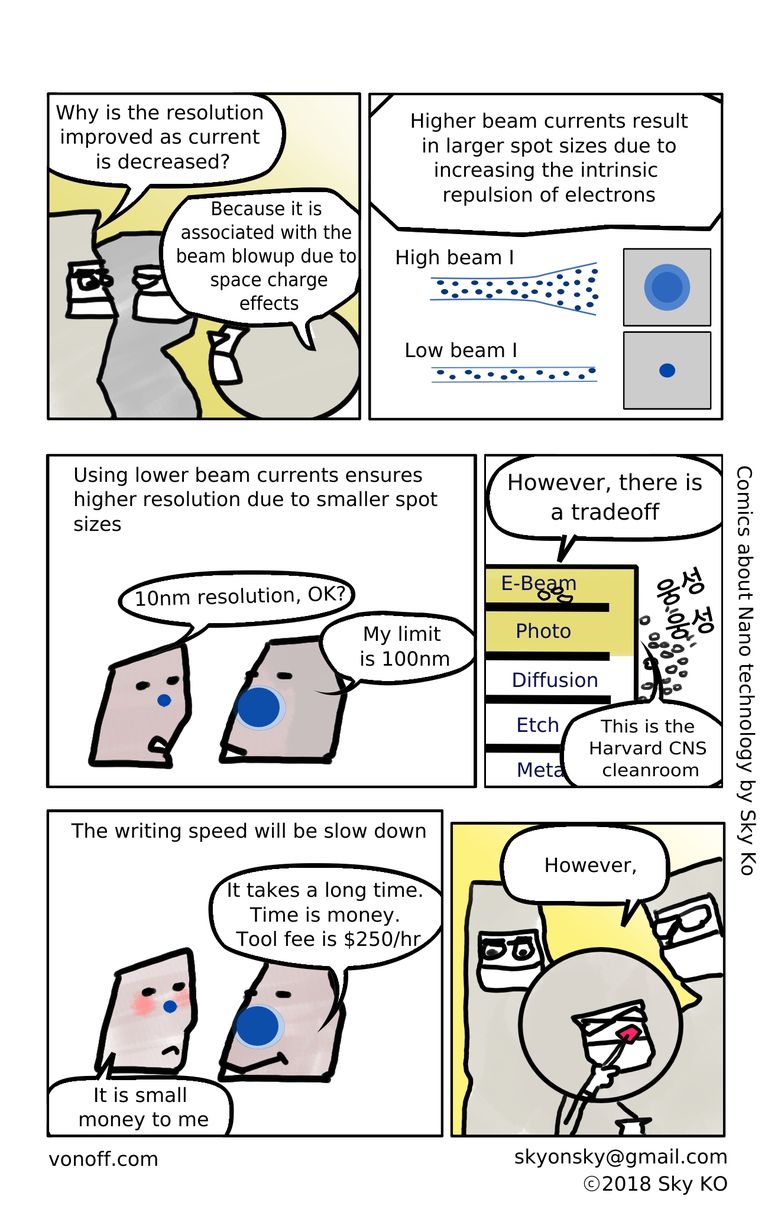

Using high beam current in EBL limits the minimum feature size due to the space charge blowup but ensures the fast writing speed. Using lower beam current ensures higher resolution but results in slow writing speed.

For a fixed beam current using E-beam resist with higher sensitivity improves the writing speed

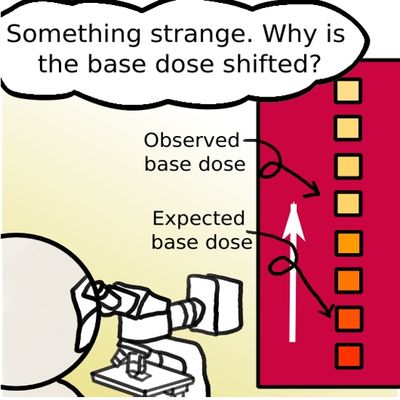

Suucessful EBL requires understanding about E-beam characteristics and parameters affecting EBL performance. Understanding your process and requirements is required to select a E-beam resist suitable for your application.

Reference

- A E Grigorescu and C W Hagen, Delft University of Technology. “Resists for sub-20-nm electron beam lithography with a focus on HSQ: state of the art.” Nanotechnology 20 (2009)

- Bo Cui, ECE, University of Waterloo; http://ece.uwaterloo.ca/~bcui/, “The electron beam lithography-2”

- Mohammad M.A., Muhammad M., Dew S.K., Stepanova M. (2012) Fundamentals of Electron Beam Exposure and Development. In: Stepanova M., Dew S. (eds) Nanofabrication. Springer, Vienna

- Nicole Devlin, et al. Georgia Technology. “Dose Determination Using ZEP520A Resist as a Model.”

- Georgia Technology. A comparison of electron beam lithography resists PMMA and ZEP520A.”

- Zeon Corporation. ZEP520A Technical report.”

- Martin M. Greve, Bodil Holst. 2013. “Optimization of an electron beam lithography instrument for fast, large area writing at 10 kV acceleration voltage.” Journal of Vacuum Science & Technology B 31, 043202

- Roberto Fallica, et al. Paul Scherrer Institute. “Lithographic performance of ZEP520A and mr-PosEBR resists exposed by electron beam and extreme ultraviolet lithography.” Journal of Vacuum Science & Technology B 35, 061603 (2017)

Leave a Reply