Summary

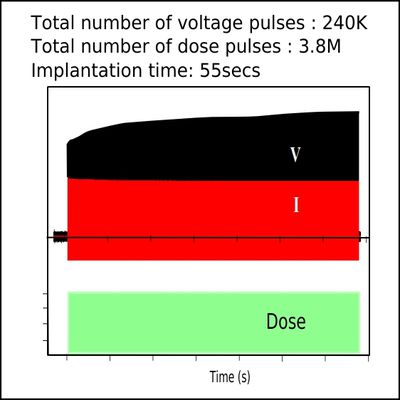

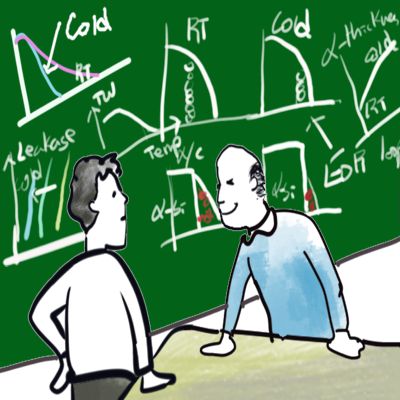

How to ensure the dose accuracy of the plasma doping or PIII system. What algorithm does the dose controller use to integrate Faraday currents?. How to ensure voltage pulse stability during implantation requiring over 300K pulses?. How to detect process faults?. What are the key parameters and how to extract them from implant pulses to characterize process quality?. I hope you can find clues in these three comics.

- select language:

- EN

Monitoring plasma ion implantation systems for fault detection and process control

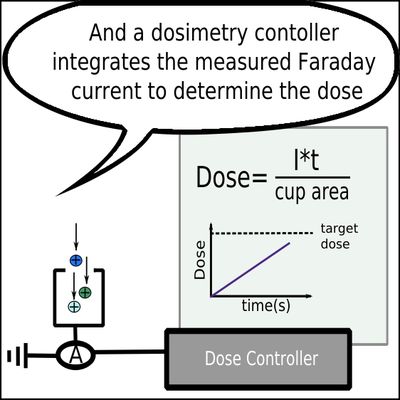

A method to monitor the plasma doping process quality is to analyze the implant pulses like DC voltage, current and Faraday current waveforms that are acquired by using high speed data acquisition unit throughout implantation. The analysis of the acquired implant pulses provides the valuable process information about dosimetry accuracy, the stability of voltage pulses, plasma arching, implant dose between pulses and fault conditions.

Dose accuracy in plasma doping

Unlike Beamline, accurate dose measurement is a big challenge for plasma immersion doping. The simple integration of the faraday current can’t accurately measure the retained dose because it is a complicated function of process condition, surface interactions and surface treatment.

Plasma doping/PIII advantages over beamline implantation

Plasma doping or plasma immersion ion implantation has few drawbacks such as no mass seperation but offers advantages such as high implant current for low energy, fast throughput, simultaneous implantation of whole wafer and 3D doping.

Reference

- Paul K. Chu. (2004). Recent developments and applications of PIII. J. Vac. Sci. Technol. B, Vol.22, No.1

- IBS. A Differentiated Plasma Doping Technology for a wide range of applications. Retrieved from www.semi.org/eu/sites/semi.org/files/docs/IBS_SEMI_May24_12.pdf

- L. Fuller/Rochester Institute of Technology, L. (n.d.). Introduction of ion implantation. Retrieved from https://people.rit.edu/lffeee/IMPLANT.pdf

- Jones, E., & Cheung, N. (1997). Plasma doping dosimetry. IEEE Transactions on Plasma Science, 25(1), 42-52. doi:10.1109/27.557484

- Qin, S. (2014). Plasma doping (PLAD) for advanced memory device manufacturing. 2014 20th International Conference on Ion Implantation Technology (IIT). doi:10.1109/iit.2014.6940017

- Qin, S., & McTeer, A. (2008). Faraday/Ion Mass Spectroscopy Dosimeter for Plasma Immersion Ion Implantation/Plasma Doping Processes of Semiconductor Manufacturing. IEEE Transactions on Plasma Science, 36(3), 828-833. doi:10.1109/tps.2008.923741

- (PDF) Plasma Immersion Ion Implantation (PIII). (n.d.). Retrieved from https://www.researchgate.net/publication/273773633-

- Z. Fang, S. Ko (2008). Monitoring plasma ion implantation systems for fault detection and process control. US20080026133A1.

- Shu Qin, Bradley, M., & Kellerman, P. (2003). Faraday dosimetry characteristics of PIII doping processes. IEEE Transactions on Plasma Science, 31(3), 369-376. doi:10.1109/tps.2003.813198

Leave a Reply